Current state of waste plastic treatment

In December 2017, China banned waste plastic imports

↓

“China shock”

- Japan has exported 1 to 1.5 million tons of waste plastic to China every year.

- Owing to the import ban imposed by China, there is nowhere for Japan’s waste plastic to go.

- There is a crisis in domestic recycling, incineration, and landfill treatment.

- Approximately 40% of intermediate treatment traders have implemented or are considering implementing restrictions on the amount of waste plastic they accept.

If this situation continues, waste plastic will be everywhere without treatment,

and waste disposal will no longer be taken for granted.

Application in waste plastic treatment

Waste plastic treatment at the location of generation is necessary along with the establishment of a recycling system and efforts to reduce waste.

(ON-SITE treatment)

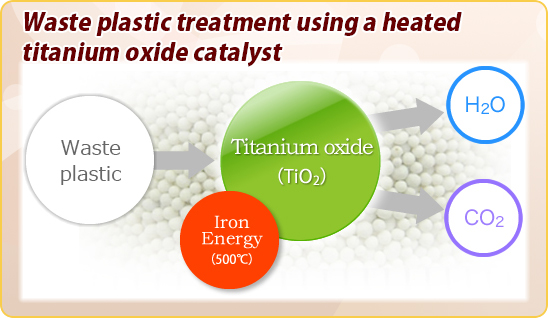

Waste plastic treatment with a heated titanium oxide catalyst

- Degradative treatment of the waste plastic discharged from factories and offices at the location of generation.

- Decomposition of waste plastic into water and carbon dioxide -> Reducing the volume to zero

- No sorting of different plastic components is necessary

- Metallic and inorganic substances that are contained in the plastics can also be collected.

Measures against waste plastic treatment problem caused by the China shock

Current state of waste in the oceans

![Current state of waste in the oceans : Drifted wastes/Ghost fishing/Effects of hazardous substances [Source: Website of Ministry of the Environment]](img/fig/fig_apply09-1.jpg)

- 80 to 90% of the waste in oceans is plastic.

- Eight million tons of plastic flows into the sea every year.

- Effects on marine organisms (accidental ingestion, ghost fishing)

- Impediment to ship navigation and the effects on tourism and fisheries

- Adverse effects on the environment and diet through the adhesion of hazardous substances

Treatment of waste in the oceans

![Different types of waste in the oceans (drifted wastes) : Fishing gear (floats)/Fishing gear (fishing nets)/Medical waste/Plastic bottles/Daily commodities [Source: Website of the Ministry of the Environment]](img/fig/fig_apply09-2.jpg)

Advantages of titanium oxide catalyst technologies

- Treatment is possible without having to sort drifted wastes comprised of a mix of vinyl chloride, PE, PP, PET, and so forth.

- The plastic waste that cannot be recycled into water (H2O) and carbon dioxide (CO2) can be decomposed.

- Fishing gear that contains metal (such as lead) as a weight can also be treated.

(Safe treatment experiment was already implemented jointly with the Japan Atomic Energy Agency (JAEA) in 2015) - It is possible to contribute to enlightenment activities following the impactful treatment method.

The titanium oxide catalyst can decompose only a resin component of carbon fiber-reinforced plastic (CFRP) to recover expensive carbon fibers without damaging the carbon fibers.

Treatment of CFRP (semi-preg) in form of woven fabric

Before treatment Black carbon fibers and a white resin are woven together. The resin is also contained at spaces between the carbon fibers.

After treatment

The resin component is completely decomposed.

Only the carbon fibers can be recovered in the form of woven fabric.

Treatment of CFRP (pre-preg) in form of sheet

Before treatmentA product obtained by forming unidirectional long carbon fibers into a sheet by using a resin

After treatmentThe resin component is completely decomposed and the carbon fibers can be recovered in the form of long fibers.

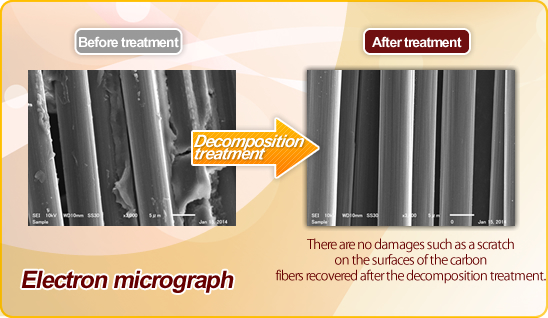

Electron micrograph

All the resin components on the surfaces of the carbon fibers and in the spaces between the carbon fibers can be completely decomposed. There are no damages such as a scratch on the surfaces of the carbon fibers recovered after the decomposition treatment.

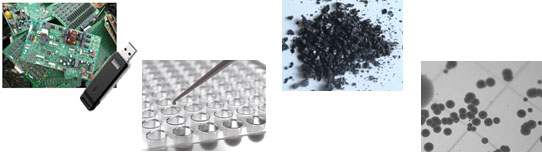

All the organic materials such as plastic in a cellular phone or a smartphone are decomposed.

Metals, glass, and the like, which are not decomposed, can be recovered.

Separation with sieve

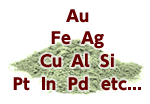

Metals, precious metals, and the like are recovered by subjecting a cellular phone or a smartphone to decomposition treatment, followed by separating inorganic materials from the titanium oxide catalyst with a sieve.

Concentration of recovered precious metal

The inorganic residue recovered through the treatment of a cellular phone or a smartphone contains precious metals such as gold and silver at high concentrations.

- Au(gold) 450ppm

- Ag(silver) 1610ppm

- In(indium) 30ppm

- Pd(palladium) 20ppm

- Cu(copper) 18.03%

*The result is obtained by analyzing an inorganic residue recovered after treatment of 10 units of cellular phones.

Recovery of valuable metals

A shredder residue discharged from a recycling plant is treated.

Various kinds of organic materials contained in the shredder residue are decomposed, and valuable metals such as iron, aluminum, and copper, and the like are recovered.

Coating removal treatment of aluminum product

An aluminum product, steel product, or the like having a surface coated with a coating material or a resin is treated.

The coating material or resin coating material on the surface is decomposed, and the aluminum product, steel product, or the like is recovered in a state of containing only valuable metals.

The treatment can be applied to products or information that one do not want to leak out, or products that are difficult to treat by existing technologies.

- Prototype

- Medium for confidential information

- Genetically modified biological specimen

- Waste material discharged from a laboratory

- Experimental animal

- Diesel soot

- Microorganism···etc.

[Treatment equipment for medical waste]

Infectious medical waste is treated in a safe manner in hospital facilities without burning it.

- Chemical decomposition treatment···chemical decomposition treatment using a reaction of the titanium oxide catalyst

- Low-temperature treatment···The treatment can be conducted at about 500°C. (The temperature in general incineration treatment is about 800°C to 1,200°C.)

The treatment of waste is completed in hospital facilities.

- Reduced infection risk···The infection risk is reduced because the medical waste is not moved.

- Reduced responsibility of waste generator···The responsibility for waste tracking and management measures can be reduced because the medical waste can be treated in hospital facilities.

In addition, there is no fear of illegal dumping by an outsourcing company.

Bacteria etc. causing the infection are also decomposed.

- Infectiveness inactivation test using Escherichia coli and Bacillus subtilis

Reduction of 99.99999% (10-7) is confirmed. - The cause of infection itself such as bacteria is decomposed.

- Besides, the temperature of 500°C sufficiently satisfies the conditions of killing bacteria.

Infectiveness inactivation test

Effectiveness on reducing infectiveness of bacteria or the like is confirmed···Reduction of 99.99% (10-4)

Reduction of 99.9999% (10-6) is recommended in consideration of safety.